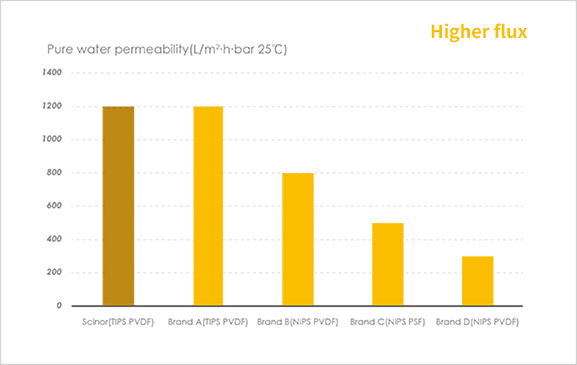

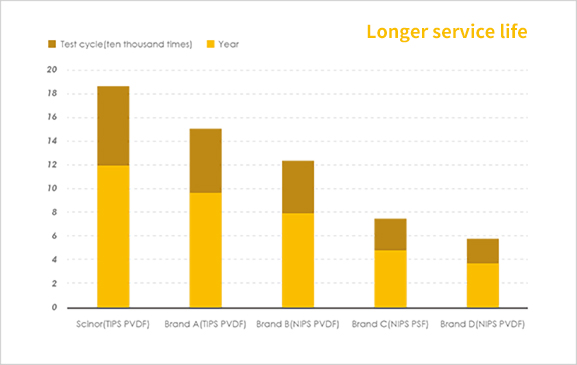

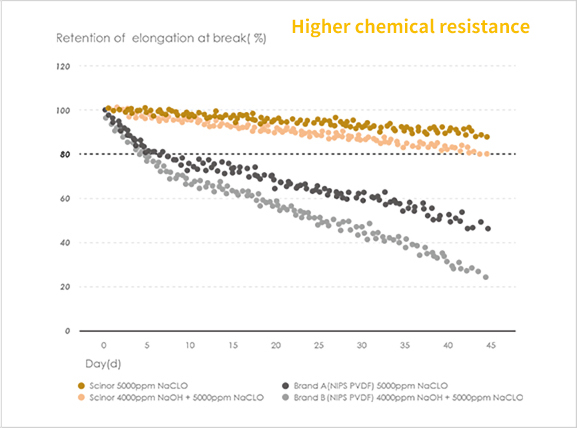

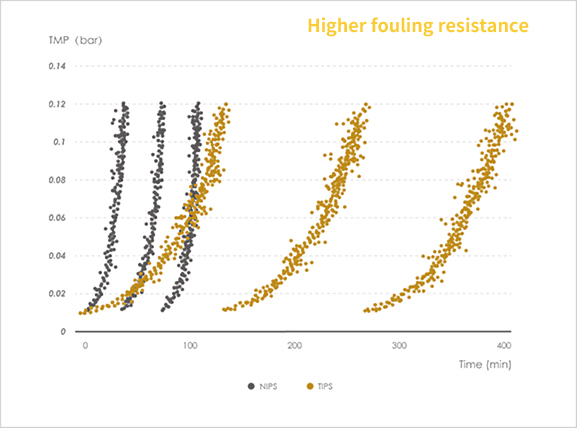

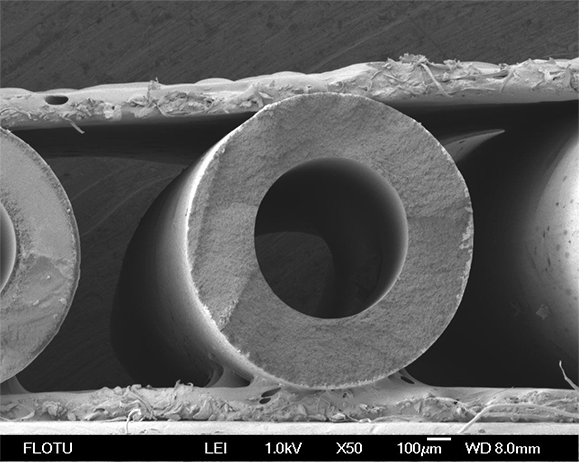

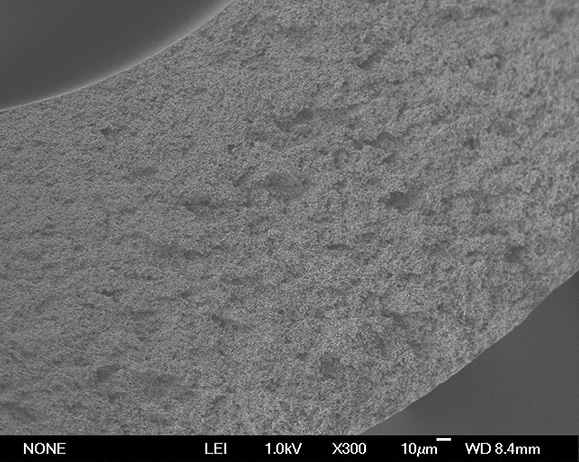

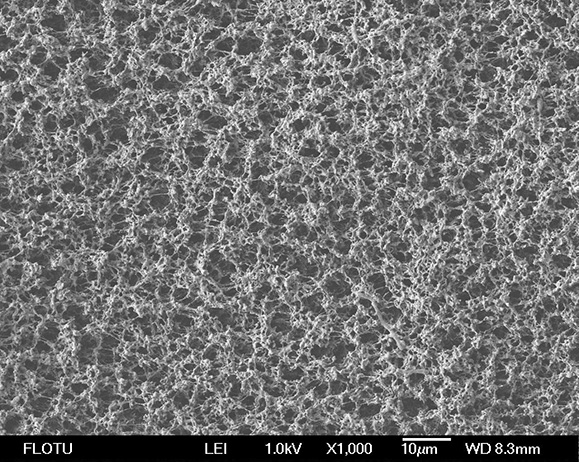

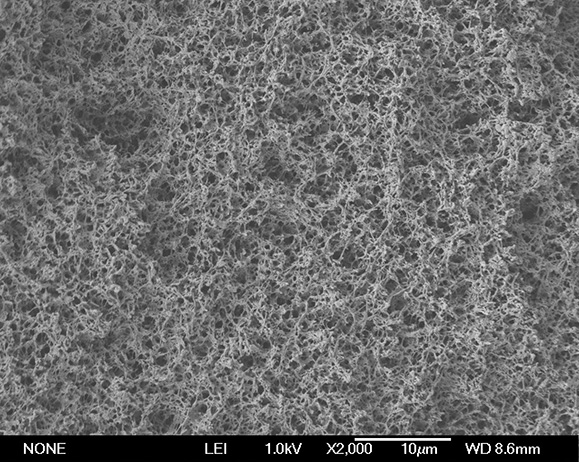

Granted the exclusive rights to the use of PVDF hollow fiber Thermally Induced Phase (liquid-liquid, L-L) Separation (TIPS) membrane preparation technology, an independent intellectual property of Tsinghua University, Scinor membrane products feature a highly-uniform pore structure, high crystallinity, high mechanical strength, high chemical stability, high flux, high separation precision, as well as world-leading bacteria and turbidity removal efficiency.

Scinor’s TIPS manufacturing line uses high-precision and highly automated equipment, producing quality-consistent and reliable products on a large scale. The automated production is controlled throughout this entire process, from the beginning of feeding to the end of spinning. The raw materials, PVDF and pore-forming agents, are weighed using a precision electronic balance, then enter the twin-screw extruder for mixing and melting under high temperature and high pressure to form a homogeneous mixture, which then is weighed again with the high-temperature melt pump and spun into hollow fiber membranes during which the temperature is reduced. The entire process is fast and has a much higher product yield than a conventional wet process.

Using a Powder mixing twin-screw extruder, continuous and automated manufacturing processes, the world's first LEAN membrane process using Soxhlet extraction - cooling crystallization – a distillation and purification recovery cycle, completely recycled extractant, yields a green and low-carbon manufacturing process.