The printing and dyeing industry is developing with plenty of trade waste. And the environment impacts it brings include large quantity of waste water, high concentration of organic pollutants, pigments and alkalinity, and fluctuant water quality, etc.

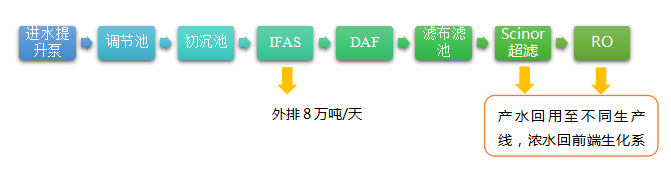

Palsana Enviro Protection Ltd. (PEPL)is one of the largest Printing & Dyeing zones in India, seeking for an available water treatment method for years. And it met Scinor in 2019, then adopted the water reuse system which was designed and implemented by Scinor alone. As a result, the treatment scale reaches 150,000 tons/day, of which the ultrafiltration water production is 70,000 tons/day, and the reverse osmosis water production is 30,000 tons/day.

Those produced water is recycled to the corresponding production line in the production process according to the water demand of different process sections.

In that sector, motivations have been adopted and obstacles were overcome successfully. The challenges are as below,

-BIM design

The wastewater reuse system adopts advanced Building Information Modeling (BIM) design to efficiently integrate data, improve the design quality and design in advance, effectively reduce waste and protect the ecological environment.

-Modular system assembly

The whole ultrafiltration system adopts modular transportation and assembly, which saves more than 50% space compared with the traditional ultrafiltration skid transportation.

At the same time, it is convenient for site installation and saves the time of system debugging.

-Water supply classification

Quality water supply is conducive to water saving. On the one hand, water quality is subdivided according to user needs to avoid high quality water used for low quality demand. On the other hand, for important users who consume large amount of water, multi-channel water supply can be adjusted and controlled according to water quality demand to reduce sewage discharge.

-Recovery improvement

The wastewater reflux method can effectively improve the utilization rate of wastewater in the plant and comprehensively regulate the amount of water.

-Reduction of wastewater

It has obvious advantages in improving industrial water quality and increasing the reuse rate of water, and the discharge of wastewater is reduced by nearly 50% compared with the original.

- Control of membrane fouling

Membrane fouling is a difficult problem in membrane treatment of wastewater, and measures should be taken from equipment configuration, membrane material, brand, operation control, chemical agent selection, cleaning scheme and so on.

Scinor ultrafiltration membrane can withstand the poor water quality of printing and dyeing wastewater and high water temperature environment, which extends the cleaning cycle while boosting cleaning recovery, reduces the system downtime, and improves the water supply efficiency of the whole park.